The Working Principle of Self-Priming Pumps: A Smart Choice That Requires No Priming

In traditional centrifugal pump systems, the pump body must be filled with liquid before starting to expel air and enable operation—a process known as “priming.” However, the advent of the self-priming pump revolutionized this cumbersome procedure. A self-priming pump is ingeniously designed with a special fluid reservoir and a gas-liquid separation chamber. When the pump starts, the impeller rotates at high speed, creating a negative pressure within the reservoir that draws air from the suction pipe into the pump body. This air mixes with the small amount of liquid remaining in the reservoir to form a gas-liquid mixture, which is then thrown out at high speed by the impeller. The gas-liquid separator then directs the gas out of the pump while the liquid cycles back into the reservoir to mix with more incoming air. This continuous cycle repeats until all the air in the suction pipe is evacuated and the liquid is drawn into the pump body, thus achieving self-priming. It is this remarkable ability to automatically clear air without external assistance that makes self-priming pumps such an efficient and convenient solution for pumping tasks.

Advantages and Limitations: Why Opt for a Self-Priming Pump?

Self-priming pumps are highly favored for their unique self-priming capability, and their benefits are quite clear. First, they drastically simplify the startup process, eliminating the hassle of manual priming. This convenience is particularly valuable in remote locations, construction sites, or homes where priming might be difficult. Second, the compact design and straightforward operation of a self-priming pump make it easy to use and maintain, reducing both the learning curve and the barrier to entry for users. Moreover, because they can handle liquids containing small amounts of gas, they perform exceptionally well in situations where the liquid level fluctuates significantly. However, self-priming pumps are not without their drawbacks. Their suction lift is typically limited, generally not exceeding a few meters, and the suction efficiency can drop significantly with higher lifts. Additionally, due to their relatively complex internal structure, their manufacturing and maintenance costs may be slightly higher than those of ordinary centrifugal pumps. Their performance might also be compromised when handling liquids with a large amount of solid particles or high viscosity. Therefore, when choosing a self-priming pump, you must weigh its pros and cons against the specific application and requirements.

Selection Guide: How to Find the Right Self-Priming Pump for You

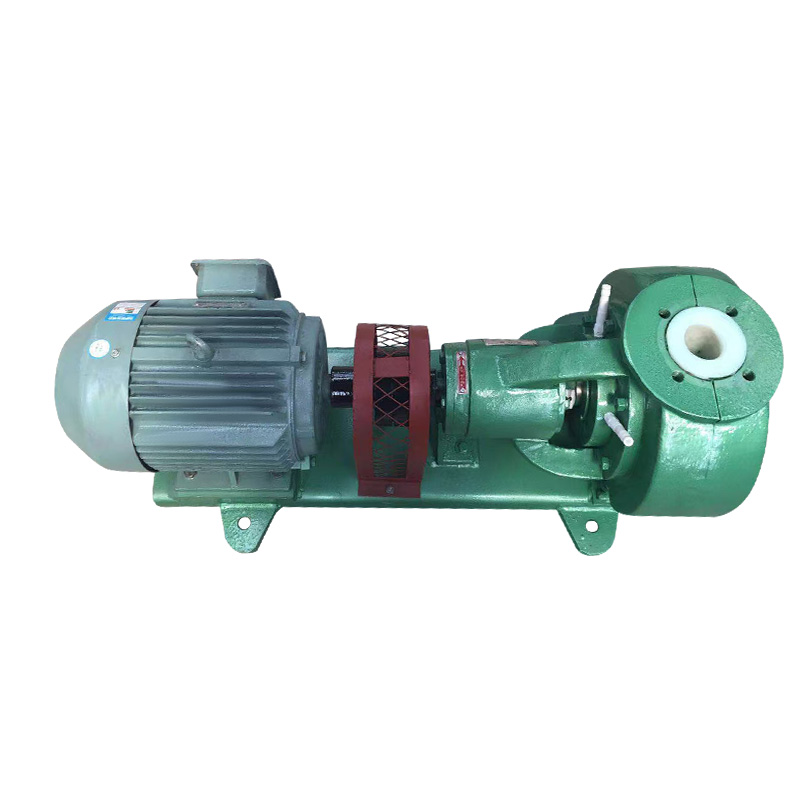

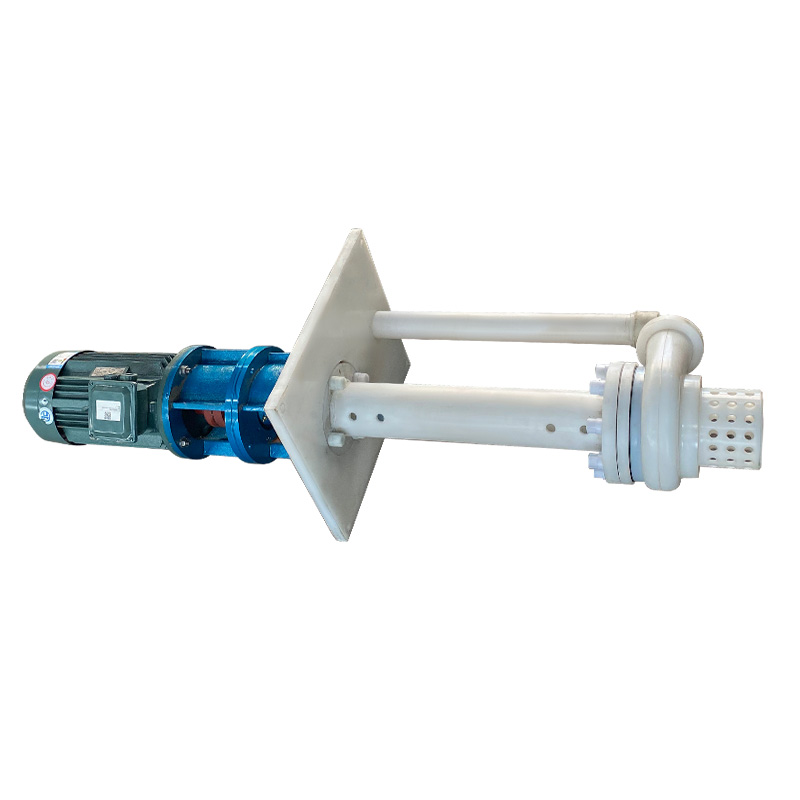

Choosing the right self-priming pump requires a comprehensive consideration of multiple factors to ensure its performance perfectly matches your needs. First, you must clarify its purpose—is it for everyday household use, agricultural irrigation, or industrial drainage? Different applications will have varying requirements for flow rate and head. The flow rate, or the volume of liquid pumped per unit of time, should be selected based on your actual needs. The head, or the height the pump can lift the liquid, must account for both the vertical and horizontal distance from the suction point to the discharge point. Next, you must consider the nature of the liquid to be pumped. If you need to handle corrosive liquids like seawater or chemicals, you must choose a corrosion-resistant self-priming pump made of stainless steel or a special material. Important factors to consider also include motor power, power supply type (single-phase or three-phase), and the pump’s specific self-priming lift. Finally, you can refer to the pump’s performance curve diagram, which visually illustrates the pump’s flow rate at different heads, helping you make a more informed decision.

Common Applications: Widespread Use from Homes to Industry

With their convenient and efficient characteristics, self-priming pumps have found widespread applications across various fields. In residential settings, they are commonly used to draw water from wells or ponds, or as booster pumps for garden watering and car washing. In agriculture, high-flow self-priming pumps are an invaluable asset for irrigation, easily drawing large volumes of water from rivers, reservoirs, or wells to provide timely and effective irrigation for crops. In industrial production, self-priming pumps are used for conveying cooling water, circulating water, or for draining accumulated water at construction sites. In marine and offshore engineering, stainless steel self-priming pumps are used for tasks like bilge water discharge and ballast water transfer, and their excellent corrosion resistance ensures reliable long-term operation in harsh marine environments. It’s safe to say that whether it’s for the small conveniences of daily life or the critical stages of industrial production, the self-priming pump plays an indispensable role.

Troubleshooting: What to Do When a Self-Priming Pump “Goes on Strike”?

Although self-priming pumps are ingeniously designed, some common problems can still occur during use, with the most frequent one being the inability to pump water. When this happens, there’s no need to panic; you can follow these steps to troubleshoot. First, check if the pump body is filled with water. Even though it’s a self-priming pump, a small amount of liquid is needed inside the body to help initiate the self-priming process, especially after the first use or a long period of inactivity. Second, check if there’s an air leak in the suction line, which is the most common reason for self-priming failure. A tiny loose joint or a damaged pipe can allow a significant amount of air to enter, destroying the negative pressure. You can use soapy water to check the joints and pipes for bubbles. Next, check if the suction end is blocked by debris like sand or leaves, which would obstruct the liquid flow. Finally, check if the power supply and motor are working properly and if the impeller is damaged. By systematically troubleshooting these steps, you can usually quickly find the root cause and fix it, getting your self-priming pump back to work.

English

English русский

русский Español

Español